Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

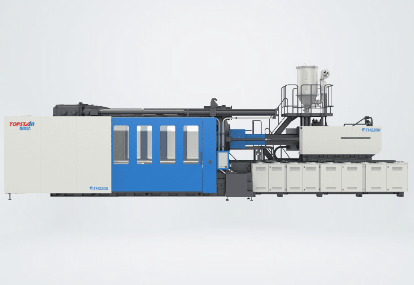

Selecting the proper injection molding machine manufacturer is a critical decision that significantly impacts your manufacturing processes’ efficiency, precision, and overall success. This comprehensive guide provides a roadmap for navigating the complex landscape of injection molding machine manufacturers. From critical criteria to quality assurance measures, we will delve into the essential considerations to ensure you make an informed and strategic choice.

Before diving into the world of injection molding machine manufacturers, it’s crucial to understand your specific manufacturing needs. This section explores how factors such as production volume, material requirements, part complexity, and industry regulations play a pivotal role in determining the type of injection molding machine and, consequently, the manufacturer that aligns with your objectives.

Machine Specifications: Define the specific technical specifications required for your production. Explore considerations such as clamping force, injection capacity, and shot weight. This segment guides you through matching machine specifications to your unique manufacturing requirements.

Technology and Innovation: Injection molding technology is continually evolving. Here, we discuss the importance of evaluating manufacturers based on their commitment to innovation, incorporation of Industry 4.0 technologies, and advancements in control systems. Stay ahead by choosing a manufacturer at the forefront of technological innovation.

Material Compatibility: Different materials demand different processing parameters. Assess how well potential manufacturers accommodate the materials crucial to your production. This part explores the significance of material compatibility in achieving optimal results and product quality.

Machine Size and Configuration: Consider the physical space available in your facility and how well it accommodates the size and configuration of the injection molding machines. This section evaluates manufacturers offering machines that fit seamlessly into your production environment.

Industry Reputation: Reputation reflects a manufacturer’s track record in the industry. This segment delves into strategies for researching and assessing the reputation of injection molding machine manufacturers, including customer reviews, testimonials, and industry rankings.

Experience and Expertise: A manufacturer’s experience and expertise contribute to their ability to meet diverse manufacturing challenges. Here, we explore the importance of evaluating a manufacturer’s history, industry tenure, and proficiency in addressing specific production requirements.

Global Presence and Support: Consideration of a manufacturer’s worldwide presence and support network is crucial for ongoing maintenance, support, and potential expansions. This section guides you through assessing likely injection molding machine manufacturers’ geographical reach and service capabilities.

ISO Certification: ISO certification is a crucial indicator of a manufacturer’s commitment to quality. Explore the significance of ISO certifications, such as ISO 9001, in ensuring that the manufacturer adheres to international quality management standards.

CE Compliance: Compliance with CE (Conformité Européenne) standards is essential for machines destined for the European market. Learn about the importance of CE compliance and how it contributes to meeting regulatory requirements and ensuring product safety.

Quality Control Measures: Investigate the quality control measures implemented by potential manufacturers. This part explores the role of quality control in maintaining consistency, precision, and reliability in the manufacturing processes.

Availability of Spare Parts: A reliable spare parts supply minimizes downtime. Explore how manufacturers manage the availability and accessibility of spare parts, ensuring that your production remains uninterrupted.

Technical Support and Training: Timely technical support and comprehensive training programs contribute to efficiently operating injection molding machines. This segment evaluates potential manufacturers’ technical support and training resources.

Maintenance Contracts: Consider the availability and terms of maintenance contracts. Assessing the options for preventive maintenance, scheduled servicing, and emergency support is essential for your machines’ longevity and optimal performance.

Initial Investment: While upfront costs are a significant consideration, this section emphasizes the importance of viewing the investment in injection molding machines as a long-term commitment. Explore strategies for balancing initial investment costs with the overall cost of ownership.

Total Cost of Ownership (TCO): TCO analysis considers factors beyond the purchase price, including maintenance, energy consumption, and operational efficiency. Understand how to conduct a comprehensive TCO analysis to make an informed decision.

Return on Investment (ROI): Calculating the ROI is essential for understanding the financial benefits of your investment over time. Assess the expected ROI based on your manufacturing needs and production projections.

Automotive Industry Success: Explore how a leading injection molding machine manufacturer contributed to the success of an automotive manufacturer, meeting high-volume production requirements with precision and efficiency.

Consumer Goods Excellence: Delve into a case study showcasing the proper injection molding machine manufacturer’s role in producing consumer goods and meeting stringent quality standards and market demands.

Medical Device Manufacturing: Investigate a success story in the medical device industry, highlighting the role of a reliable injection molding machine manufacturer in achieving precision, consistency, and compliance with regulatory standards.

This section provides a step-by-step guide on synthesizing the gathered information, weighing the factors, and making an informed decision when selecting the proper injection molding machine manufacturer. It covers the importance of creating a scoring system, conducting site visits, and engaging in thorough discussions with potential manufacturers. Emphasis is placed on fostering effective communication to ensure that your unique production needs align with the capabilities of the chosen manufacturer.

Given the rapid pace of technological advancements in the injection molding industry, this section explores strategies for future-proofing your investment. It discusses the importance of choosing a manufacturer committed to ongoing research and development and incorporating emerging technologies that can enhance the longevity and relevance of your injection molding machines.

Selecting the proper injection molding machine manufacturer is a strategic decision that goes beyond the immediate needs of your production. This guide has walked you through the crucial criteria, considerations, and quality assurance measures necessary for making an informed choice. By understanding your manufacturing needs, evaluating manufacturers based on reputation and experience, ensuring quality assurance and support, considering budgetary factors, and exploring real-world case studies, you are better equipped to forge a strategic partnership that contributes to the long-term success of your manufacturing endeavors. The proper injection molding machine manufacturer is not just a supplier but a collaborator in your journey toward manufacturing excellence.