Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Transfer tapes are versatile adhesive products used in various industries for bonding and mounting applications. From industrial manufacturing to electronic assembly, transfer tapes offer a convenient and efficient solution for joining surfaces. This article aims to provide a comprehensive guide to Transfer Tapes, exploring their types, applications, advantages, and best practices for maximizing efficiency.

Single-sided transfer tapes feature adhesive on one side, making them ideal for bonding applications where only one surface needs to be adhered.

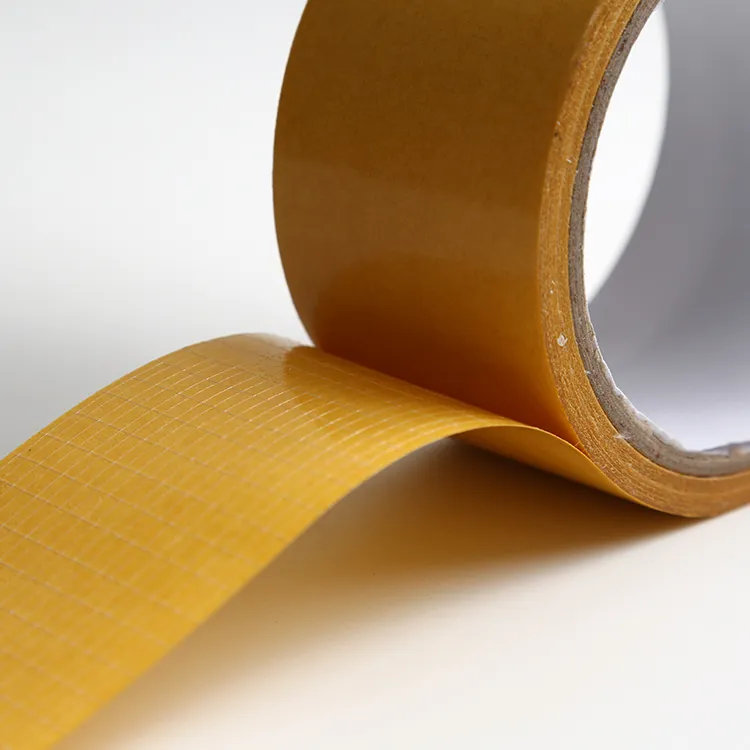

Double-sided transfer tapes have adhesive on both sides, allowing for bonding between two surfaces. They are commonly used in applications requiring a strong and permanent bond.

Foam transfer tapes consist of a foam carrier with adhesive on both sides. They are designed to conform to irregular surfaces, providing excellent cushioning and vibration damping properties.

Transfer tapes find extensive use across various industries due to their versatility and reliability.

In the industrial sector, transfer tapes are used for bonding components in assembly operations, sealing gaskets, and mounting signage.

Transfer tapes play a crucial role in automotive assembly, from bonding trim components to attaching emblems and badges.

In electronics manufacturing, transfer tapes are utilized for attaching displays, bonding touchscreens, and securing components on circuit boards.

Transfer tapes are employed in medical devices and equipment assembly, providing secure bonding for sensors, electrodes, and other components.

Transfer tapes offer several advantages over traditional bonding methods.

Transfer tapes can bond a wide range of substrates, including metal, plastic, glass, and wood, making them suitable for diverse applications.

With excellent resistance to moisture, chemicals, and temperature extremes, transfer tapes ensure long-lasting bonding performance.

The pressure-sensitive adhesive allows for easy application without the need for additional curing time or equipment.

Selecting the appropriate transfer tape is essential for achieving optimal results.

Consider the surface material and its properties to ensure compatibility with the transfer tape adhesive.

Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select a transfer tape that can withstand these conditions.

Assess the surface energy of the substrates to determine the adhesive strength required for bonding.

Proper application techniques are critical for ensuring successful bonding with transfer tapes.

Clean the surfaces thoroughly to remove dirt, oil, and other contaminants that can affect adhesion.

Apply uniform pressure to ensure intimate contact between the tape and the substrate, promoting strong bonding.

Apply sufficient pressure and maintain the recommended temperature range during application to activate the adhesive effectively.

Follow these tips to maximize the efficiency of transfer tape applications.

Store transfer tapes in a cool, dry place away from direct sunlight to maintain their adhesive properties.

Handle transfer tapes carefully to avoid damage to the adhesive surface, which can affect bonding performance.

Address common issues such as air entrapment, poor adhesion, or adhesive residue promptly to ensure optimal bonding results.

Apart from performance benefits, transfer tapes offer cost-effectiveness and sustainability advantages.

The efficiency and durability of transfer tapes can result in cost savings over time compared to traditional bonding methods.

Transfer tapes minimize waste and environmental impact by eliminating the need for mechanical fasteners or solvent-based adhesives.

Real-life examples and success stories demonstrate the effectiveness of transfer tapes in various applications.

Case studies highlight how transfer tapes have improved assembly processes, reduced production costs, and enhanced product performance.

Customer testimonials provide firsthand accounts of the benefits and advantages of using transfer tapes in specific applications.

The future of transfer tape technology holds promising innovations and advancements.

Ongoing research and development efforts aim to enhance the performance, versatility, and sustainability of transfer tapes.

The increasing demand for lightweight and durable bonding solutions is expected to drive the growth of the transfer tape market in the coming years.

In conclusion, transfer tapes offer a versatile and efficient solution for bonding and mounting applications across various industries. By understanding the different types of transfer tapes, their applications, advantages, and best practices for usage, businesses can maximize efficiency and achieve superior bonding results.